Innovation and the environment are two of the fundamental guidelines that guide our path. This is why we focus on various projects related to these areas. At present, at Grupo Técnico RIVI we continue to work on the development and manufacture of the nanobubble generation system for the COZERO project.

¿What is COZERO?

The full name of COZERO is Bio CO2 generated in the industry and it is a project supported by the Ministry of Industry, Trade and Tourism, and included in its Support Programme for Innovative Business Groups (AEI) as a Mechanism for Recovery, Transformation and Resilience. This project is part of our strategic line of compliance, commitment to the decarbonisation of industry and corporate social responsibility.

In this project, Grupo Técnico RIVI is part of a team of innovative companies committed to a sustainable industry; ZINNAE (Cluster for the efficient use of water), Ingeobras, y DAB Biotechnology. Each of us brings our know-how in a different field to the project, in order to meet the challenge of emissions reduction and climate change with a high guarantee of success.

We are aware that achieving the objective of a sustainable industry can only be achieved through innovation, the development of new sustainable technologies, public aid and the economic viability of the projects. The COZERO project meets all of these criteria.

¿What is COZERO?

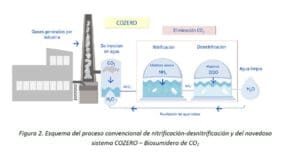

COZERO aims to develop a technology capable of eliminating CO2 from industrial emissions by means of a biotechnological nitrification process. This process will use CO2 from combustion in industrial processes as a source of inorganic carbon. This will be achieved in an efficient way with the application of nano bubbles to increase the transfer of matter from the gas into the liquid. The CO2 will feed a bioreactor to which ammonium will be added to carry out the aerobic nitrification reaction. COZERO's circular economy makes it possible to close the nitrogen and water cycle, in line with environmentally sustainable technology.

¿What does Grupo Técnico RIVI contribute to this ecosystem?

At G. T. RIVI we are experts in fluid circulation technologies, including the design and programming of the monitoring and control panels and the implementation of IOT and Artificial Intelligence in this type of systems. For this project, our responsibilities are focused on the manufacture and integration of the nano bubble generation system, the CO2 and resulting gas control and circulation system, as well as the design, manufacture and commissioning of the process monitoring and remote control system. By monitoring the system, it is possible to obtain as much data as possible on the variables that influence the process. This data can be analysed to obtain valuable information about the efficiency of the process, detect anomalies or trends, and make decisions based on this data to optimise the production and quality of the biological processes. In biological processes, the IoT implemented by G.T. RIVI will allow remote and real-time monitoring of the equipment, being able to control, for example, the nutrient levels in a bioreactor or supervise the operating variables (pH, HRT, temperature...). This provides greater flexibility and efficiency in the management of biological processes, while allowing the generation of a product in line with Industry 4.0, helping its future commercialisation.

In short, at RIVI we are committed to a sustainable future and to make it possible, we invest and work on the decarbonisation of the industry through our strong commitment to innovation and the development of new technologies.